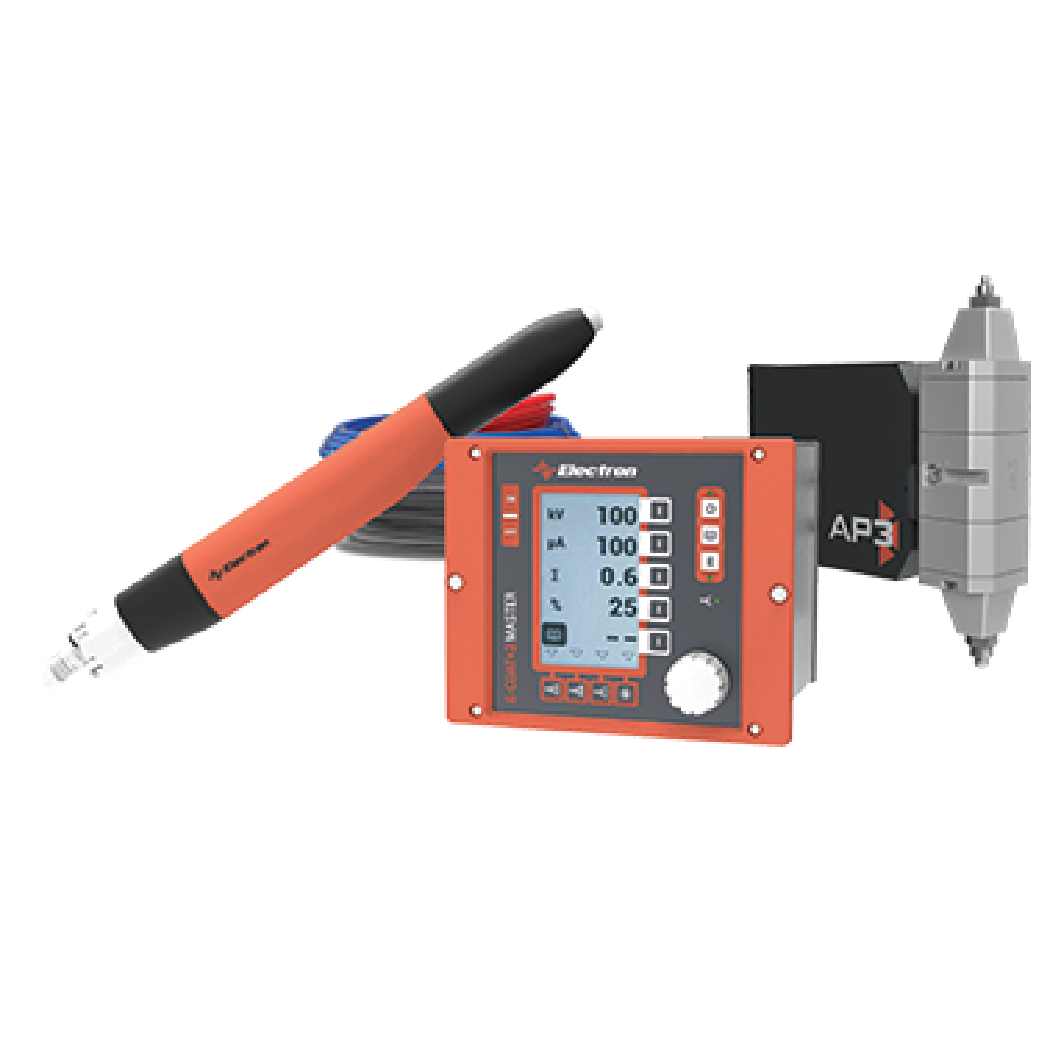

Powder Coating Devices

E-COAT+3 MASTER P3 Series devices are pump-fedupper segment devices where pneumatic and electrical parameters are digitally controlled through the front panel. While electrical controls remain dependent on voltage and current, it provides the ability to proportionally adjust the air values of the application pump.

The factory settings, along with 50 different customizable electrical/pneumatic specifications, dual triggering options, PLC automation and bluetooth connectivity, make the E-COAT+3 MASTER P3 the optimal solution for especially advanced manual and automated applications where it is necessary to pump the powder for high surface quality and/or higher powder output.

The patented E-Feed+3 AP3 application pump, featuring TriFlow technology, delivers outstanding powder output of up to 900 grams per minute. It ensures a flawless coating process throughdense-phase powder transfer, providing a truly exceptional painting experience.

SIMPLE AND COMPACT DESIGN

.

5.0-inch TFT screen

.

TRIFLOW TECHOLOGY Patented

.

ROTATABLE HEAD

.

EQUIPMENT INCLUDED IN THE SERIES

Advanced Control and Performance

- Accurate static voltage and current control with feedback

- Hybrid proportional valve system not affected by inlet pressure changes

- Proportional and independent pneumatic adjustment option

- Ability to save 50 different prescriptions

- 4 quick prescription options

- Easy operation thanks to the rotating adjustment knob

- Remote control feature with buttons on the gun

- Compatibility with automation systems thanks toTCP / IP connection

- Fast navigation between recipes with double triggering

- Quick control of the work with built-in LED lighting

- Data log and analysis thanks to Bluetooth connection

- World's strong loading performance with 120kV-120µA charging capacity

- Excellent coating even on difficult surfaces thanks to microcharging control below10 µA

- Powder transfer capacity up to 950 g/min thanks to our latest AP3 pump