Powder Coating Devices

PART DETECTION SYSTEMS

Product recognition sensors for paint booths. Thanks to the sensors; a homogeneous powder coating is obtained on the surfaces. At the same time, dust is saved and the amount of excess spray is reduced. The manual coating process is reduced and efficient powder coating of complex workpieces is achieved.

E-SENSE+3 BASIC

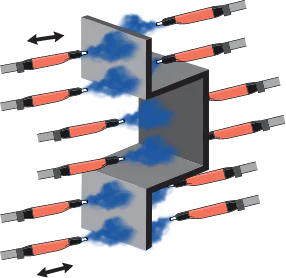

GAP DETECTION SYSTEM

Detecting part gaps

Simultaneous closing and opening of all guns in the gaps.

E-SENSE+3 1D

VERTICAL PART DETECTION SYSTEM

Detecting workpiece gaps

Automatic measurement of workpiece height

Automatic closing of non-essential pistols according to workpiece height

E-SENSE+3 2D

FULL PART DETECTION SYSTEM

· Detecting workpiece gaps

· Automatic measurement of workpiece height and width

· Automatic closing of non-essential pistols according to workpiece height

· Automatic adjustment of the painting distance of all guns on each side according to the workpiece width

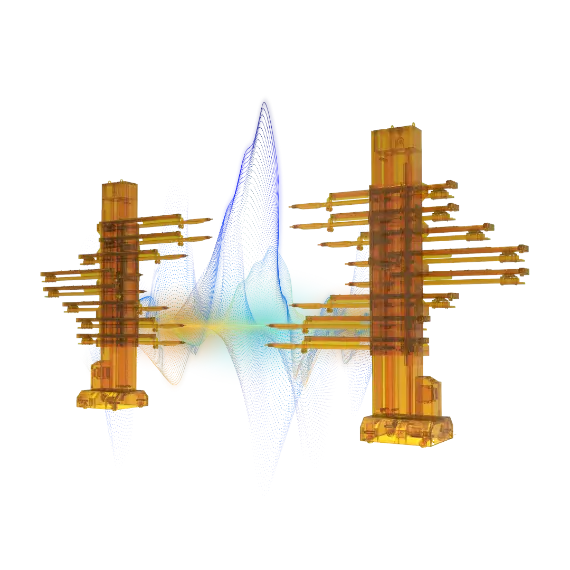

E-SENSE+3 3D

DYNAMIC COUNTOUR DETECTION SYSTEM

Detailed detection of part gaps.

Detailed measurements of the height and width of the part.

Automatic closing of non-essential pistols according to workpiece height

HIGH PRECISION

.

AUTO-SENSING SENSING

.

HIGH REPEATABILITY

.

DATA COLLECTION

.

Automatic gun positioning in accordance with the detected workpiece geometry thanks to the information on the workpiece surface map

Homogeneous powder thickness even on the most complex workpieces thanks to the independent gun distance feature

Independent gun distance adjustment for homogeneous coating of complex parts

E-SENSE+3 series is a critical investment to increase precision, quality and efficiency in powder coating processes and significantly improves the level of automation of powder coating processes.

Technical Document